At Helios Marine, every product we build floats on the foundation of smart, safe, and scalable battery technology. But our journey to a vertically integrated energy system didn’t start with factory-fresh packs. It started where innovation often begins—in the scrapyard, rethinking what already exists.

To understand how we got here, it is important to understand the chemistry that powers everything.

Understanding the Foundation: NMC vs. LFP

Most modern lithium-ion batteries used in electric vehicles fall into two main chemistries:

- NMC – Lithium Nickel Manganese Cobalt Oxide

- LFP – Lithium Iron Phosphate

NMC cells (in formats like NMC111, NMC532, and NMC811) are known for high energy density, which makes them ideal for electric vehicles with limited space and long-range requirements. They’re widely used across the automotive industry, from BMW to Jaguar and beyond.

However, NMC has its drawbacks:

- Lower thermal stability, with increased fire risk in marine environments

- Shorter cycle life, especially under daily heavy use

- Dependence on cobalt and nickel, with ethical and supply chain concerns

By contrast, LFP (Lithium Iron Phosphate) chemistry offers:

- Superior safety and thermal resistance

- Much longer cycle life (2–3 times that of NMC in many cases)

- Lower cost, and no cobalt or nickel

- Slightly lower energy density, but easier thermal management and packaging

For boats—where safety, stability, and lifespan matter more than squeezing out maximum energy per cubic centimeter—LFP is the smarter long-term solution.

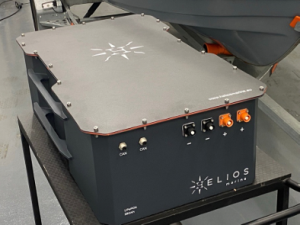

Phase One: BMW i3 Modules and Custom Controls

We began our development journey with BMW i3 NMC modules, repurposing them for the Helios SGP 4.3 prototype by connecting three modules in parallel. These automotive packs were designed for city use—not open waters.

To make them work in marine conditions, we developed a custom-modified BMS and controller interface, translating the battery’s native automotive signals to marine operational logic. This was high-tech at the time – allowing us to test thermal behavior, discharge patterns, and safe CAN integration in real-world marine environments.

We quickly learned that while the i3 modules delivered the energy, they were not made for vibration, salt, or the sudden current draws common in boating. But it worked—and it validated our engineering instincts.

Phase Two: Jaguar EV Packs – Smarter, Stronger, Still NMC

For the next evolution, we sourced modules from autonomous Jaguar EVs (originally deployed in the Waymo fleet). These packs offered improved form factor, better discharge capability, and a tougher build.

Again, we used Helios-custom BMS adaptations and control logic, bridging the gap between EV technology and marine propulsion systems. The result was a compact and powerful 48V battery platform, suitable for both electric outboards and storage banks.

This setup helped us refine modularity, data handling, and protective logic. But we still battled the same NMC limitations: heat sensitivity and lifespan concerns under sustained marine loads.

Photo Credits: Helios Marine

Phase Three: Prismatic LFP – Safe, Stable, but Underpowered

With growing experience and ambition, we transitioned to prismatic-format LFP cells—a well known solution for stationary storage and hybrid marine systems.

The benefits were clear:

- Outstanding safety

- Simple integration

- Long service life

But the downside was performance. These cells had a low C-rate, meaning they couldn’t safely sustain high current discharge required for direct propulsion. For storage? Excellent. For drive systems? Insufficient. We needed a chemistry that could both store energy and deliver it instantly.

Photo Credits: Helios Marine

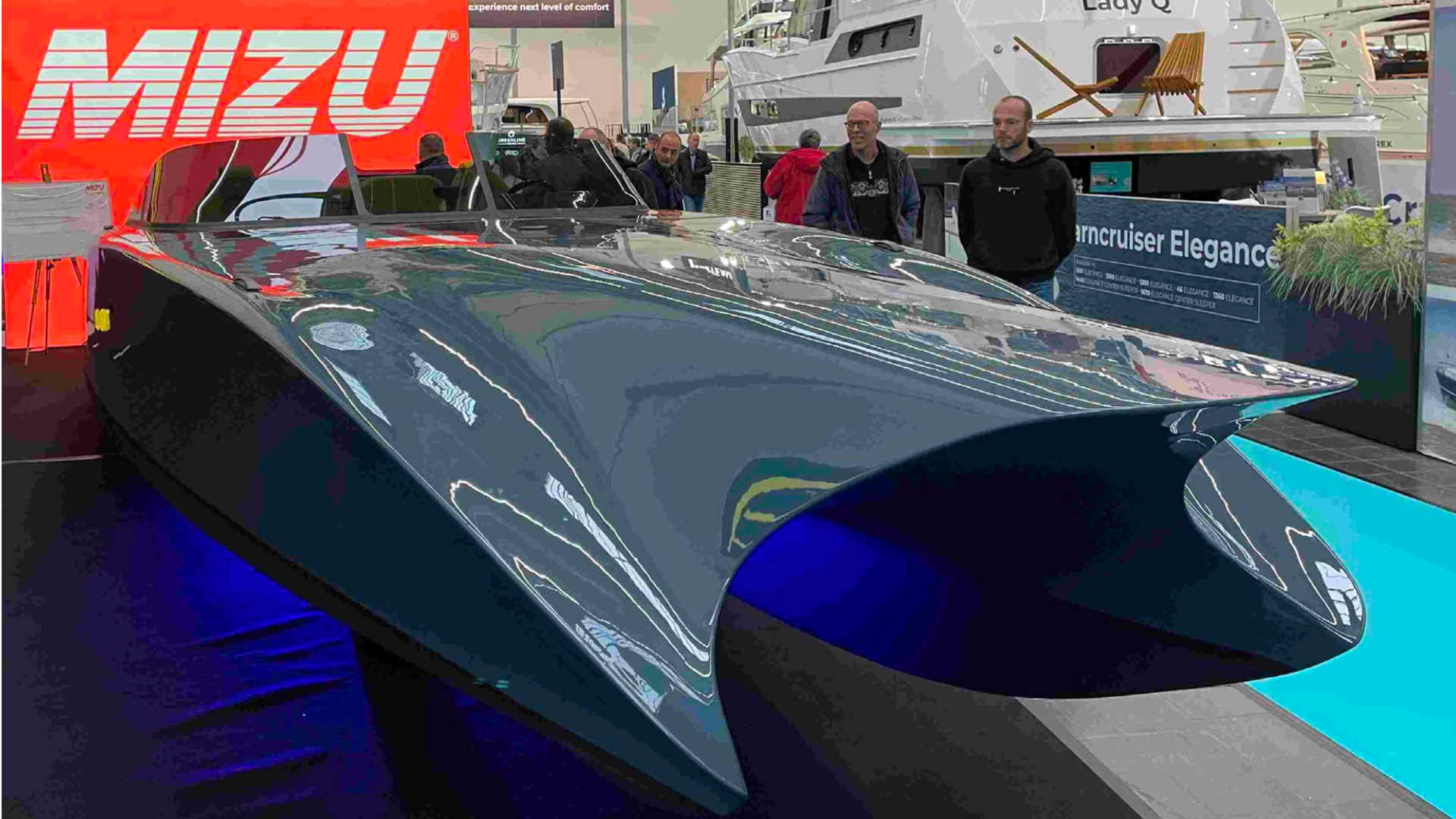

Phase Four: Blade-Format LFP – Built for the Sea

Today, our systems are powered by marine-optimized LFP blade cells, engineered specifically for harsh environments and dynamic marine use.

Why blade cells changed everything:

- High continuous and peak discharge capability

- Efficient cooling thanks to their flat surface and long format

- Reinforced construction against shock, salt, and vibration

- Safe thermal behavior under all loading conditions

- Extended cycle life, delivering reliable propulsion over years

These cells are not automotive leftovers. They’re purpose-built for vessels—and they now power our next-generation electric boats, energy banks, and hybrid systems.

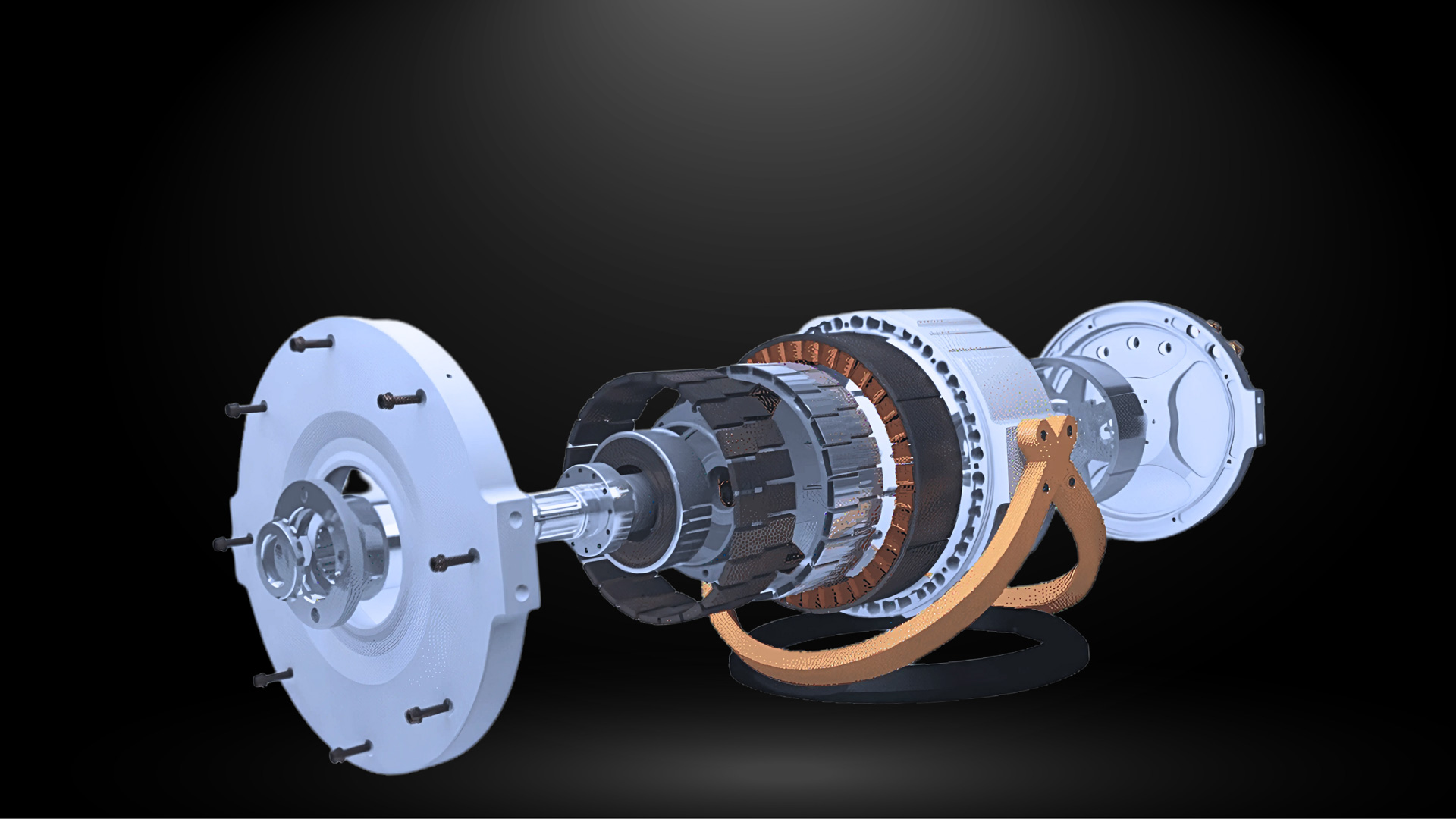

Why Helios Builds Its Own Batteries Now

We don’t stop at sourcing good cells. We engineer the entire battery system—mechanical housing, thermal management, communication, safety logic, and software integration—under one roof.

This full-stack control gives us:

- Plug-and-play compatibility with our propulsion and digital systems

- Deeper diagnostics and real-time fleet insights

- Faster R&D iterations and custom configurations

- True vertical integration across energy, hardware, and software

In other words: our batteries don’t just power the boat—they think with it.

The Takeaway: Built From Experience, Designed for the Sea

Every pack we have built—from BMW i3 trials to our current marine-grade blade batteries—has taught us something. We’ve outgrown NMC, outperformed prismatic, and now operate with cells engineered for one environment: the sea.

But we haven’t turned our backs on second-life batteries. On the contrary – we believe they still have a valuable future. When used intelligently and within proper limits on discharge rate, thermal management, and capacity, repurposed EV modules can power medium-output marine applications reliably and sustainably.

At Helios, we’ve built the know-how to do it right. And when the time is right, we’ll get back to it.

Drago Enchev

CEO, Helios Marine