Why Commercial Boats are Leading the Shift

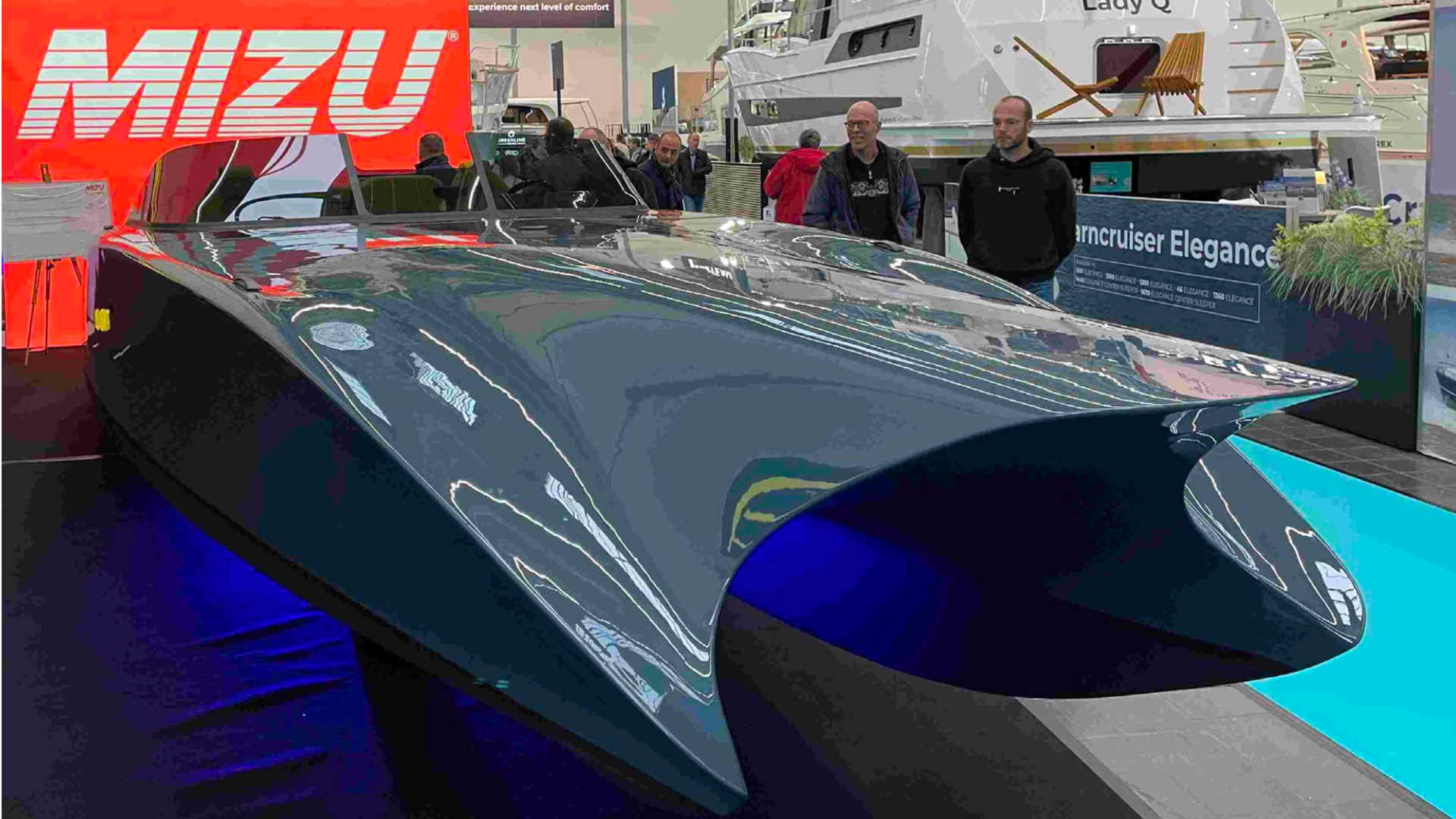

Marine electrification is moving from pilot to practice. Ferries, workboats, and inland barges are natural early adopters because they run predictable duty cycles like fixed routes, repeatable schedules, and dependable charging windows. Those characteristics make battery behavior far easier to model and manage than in leisure or deep-sea applications, and they align with the industry momentum highlighted in recent battery market overviews.

Yet adoption hinges on trust, that batteries will deliver rated life under real operating stress, that safety margins are proven, and that total cost of ownership (TCO) is truly favorable.

Using predictive analytics, trust can be gained by turning raw battery data into forward-looking guidance on life, safety, and ROI.

That’s where predictive analytics comes in.

The Commercial Marine Battery Challenge

Upfront Cost Concentration

Batteries can dominate vessel CAPEX; in niche marine volumes, pack costs remain materially higher than mass-market automotive, even as global average pack prices fell sharply in 2024.

Heavy, Sustained Loads

Commercial vessels can operate near continuous ~1C discharge for planing/steady service far more demanding than typical automotive drive cycles (noted widely by operators and technical teams in practice).

A Data and Trust Gap

Operators regularly report discrepancies between supplier data-sheets and real-world performance, making life predictions and warranties difficult to rely on without independent analytics. Independent analysis has also shown how basic SOC/SoH estimation approaches can deviate significantly under LFP chemistries pointing to the need for more sophisticated, cloud-assisted methods.

Why Predictable Duty Cycles Are a Superpower: Digital Twins for Commercial Electric Boats

Commercial boats excel where the route, dwell, and power profile repeat:

- Ferries: fixed crossings with charging at both ends.

- Harbor workboats: repeat tasks within ports, predictable push/pull power needs and idle windows.

- Inland barges: repetitive canal/river routes with set waypoints.

This repeatability is perfect for digital twins; virtual models tuned with real telemetry that forecast degradation with far more accuracy than generic curves. SMART’s approach ingests live voltage, current, temperature, and impedance to detect subtle trends long before conventional QA would.

How Predictive Analytics Extends Life, Improves Safety, and Boosts ROI

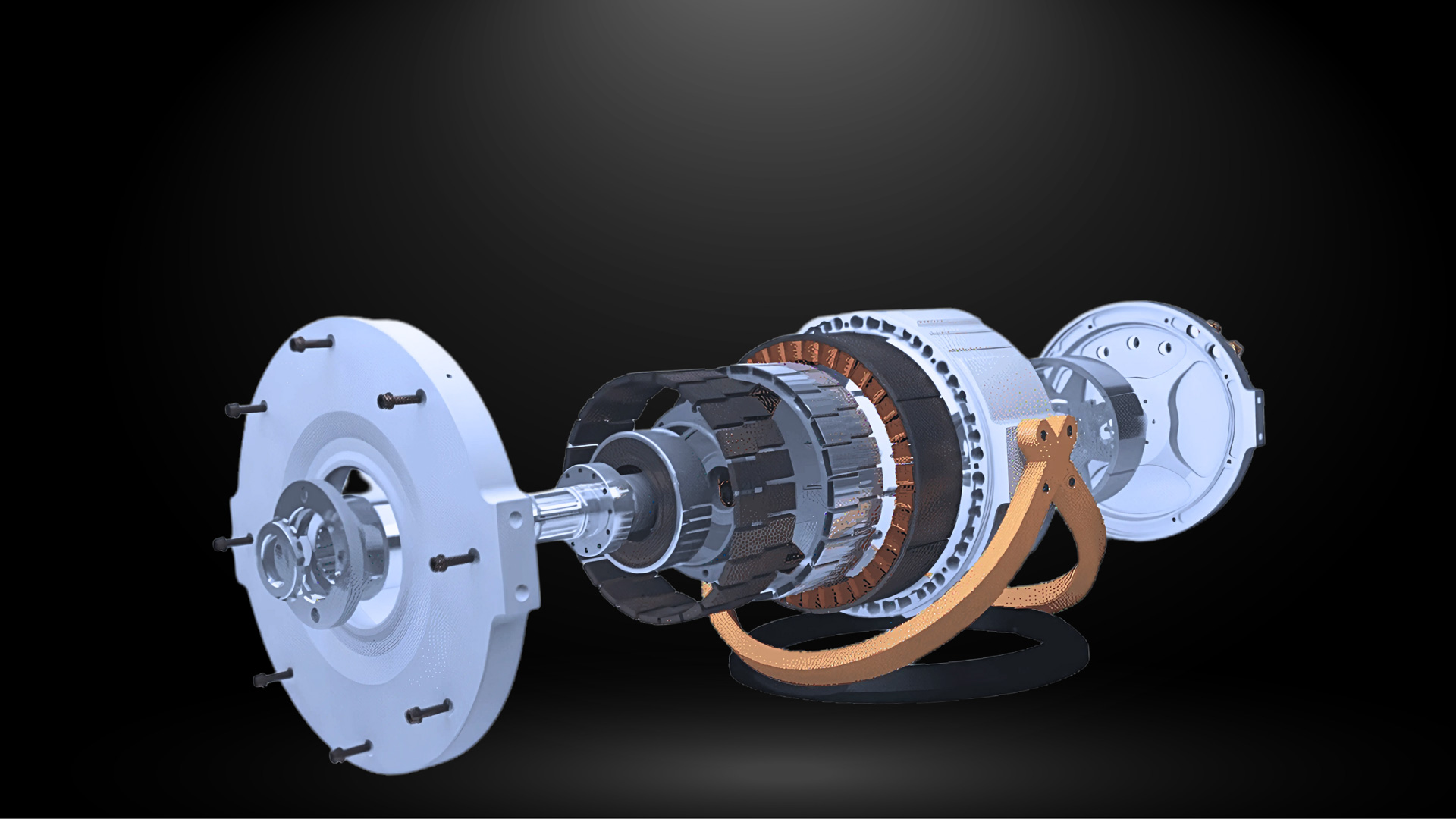

Digital Twins for Marine Batteries

A digital twin mirrors each pack/module and the vessel’s actual duty cycle. Operators can safely test “what-ifs” (summer ridership spikes, partial vs. full overnight charges, different ambient/thermal conditions) and see the life and risk impact before changing operations. DT framework emphasizes continuous, high-fidelity telemetry (V, I, T, EIS/impedance when available) to surface degradation pathways weeks to months earlier than basic BMS estimates.

Early Fault Detection & Safety

Marine packs face harsher realities; salt fog, vibration, sustained loads, immersion/plate cooling quirks. Predictive analytics looks for precursor signals (creeping impedance, imbalance drift, hotspot trends) that precede capacity or safety events. For passenger ferries and port assets, this preemptive assurance supports permitting and insurance conversations by demonstrating quantified risk reduction.

Maximizing ROI and Finance-ability

With accurate life forecasts, operators can:

- Right-time replacements (avoiding premature retirements while sidestepping in-season failures).

- Refine charging policies (e.g., mid-SoC holds to cut cycle aging, targeted fast charging when life-neutral).

- Underpin financing with data-backed TCO curves for lenders/insurers.

This shift—batteries as predictable assets rather than uncertain liabilities—is key to accelerating adoption.

Real-World Momentum: Ferries, Tugs, and Barges

Scandinavian Electric Ferries

- Norled “Ampere” (Norway) launched the modern wave of e-ferries, operating short, frequent crossings on a 1 MWh pack with rapid turn-charging proving the viability of predictable, high-frequency routes for batteries.

- “Ellen” (Denmark), an EU-backed E-Ferry project, demonstrated long all-electric legs (≈21.4 nautical miles) on a ~4.3 MWh system—evidence that careful route design and charging windows make even longer commuter links practical.

U.S. Harbor Workboats (tugs)

- Crowley “eWolf” (San Diego, CA) is the first all-electric ship-assist tug in U.S. service, delivered January 2024 and christened June 2024, supported by a purpose-built shoreside charging system and multi-agency funding. This is exactly the predictable, high-load, short-route profile where predictive analytics excels at spotting module-level divergence before it hits availability.

European Inland Barges

- The Netherlands and neighbors are pushing electric inland barges with swappable or shore-charged batteries on repetitive canal routes—an archetype for digital-twin-driven planning (charging dwell optimization, life vs. charge-rate tradeoffs) to keep packs on an 8–10 year ROI plan.

Industry Context

Across segments, 2024 saw major pricing and capacity shifts in batteries (global averages fell, deployments accelerated, AI spread across the value chain) tailwinds that help marine electrification as supply chains mature and analytics improve.

Common Standards → Trusted Adoption

One of the greatest barriers to large-scale marine electrification is the absence of common standards for measuring and reporting battery performance. Today, operators are forced to rely on supplier datasheets that often fail to reflect real-world duty cycles. Lenders and insurers face similar uncertainty, making it difficult to finance vessels at scale.

SMART’s predictive analytics solution addresses this gap by providing transparent, verifiable metrics that can serve as the basis for shared standards:

- Quantify life and safety in each operating profile. By modeling degradation and detecting early warning signs, operators gain confidence that batteries can deliver their promised lifespan under specific routes, loads, and charging schedules.

- Validate supplier claims against field reality. Predictive tools compare real-world data against manufacturer specifications, exposing discrepancies and creating accountability across the supply chain.

- Produce finance-ready TCO models operators and lenders can trust. With accurate lifecycle forecasts, shipowners can plan replacements more precisely, and financiers can underwrite projects based on real performance instead of conservative assumptions.

By moving the industry toward consistent, data-driven standards, predictive analytics transforms batteries from high-risk components into bankable assets. This common framework is what will ultimately unlock scale, accelerating adoption across ferries, workboats, and barges while ensuring safety and profitability remain at the forefront.

What Predictive Analytics Can Do in Different Sectors

Insurance Companies

Predictive analytics can lower risk exposure by providing accurate, real-time estimates of battery state of health (SOH). This enables insurers to set premiums that reflect actual risk rather than broad averages. For example, advances in machine learning and hybrid model/data-driven methods allow SOH prediction under varied, real-world operating conditions. This directly reduces uncertainty in lifetime and failure risks, which in turn lowers warranty and insurance costs.

Commercial Marine Operators

For shipping companies, predictive analytics lowers investment risk by enabling better maintenance scheduling and extending the usable life of onboard battery systems. Accurate forecasting of degradation and failures helps avoid costly unscheduled downtime. Multi-year field studies on battery storage show that operational data can reliably predict capacity fade, enabling operators to anticipate replacement needs years in advance.

Commercial Ship Builders

Shipbuilders benefit in two ways:

- Sales process – Demonstrating predictive analytics tools provides customers with confidence that lifecycle costs and risks are well understood.

- Warranty management – Predictive SOH estimation helps identify whether a failure is due to normal ageing or misuse, reducing disputes and costs from warranty claims. The EU’s new battery regulations explicitly require transparent SOH estimation methods, which predictive analytics can provide.

Examples of Predictive Analytics Already in Use

Hybrid Gaussian Process Regression (Oxford/RWTH study)

Researchers developed a recursive Gaussian process regression method to forecast battery SOH under variable conditions. The system provided accurate predictions of capacity and internal resistance, showing that real-world degradation can be forecast with high accuracy—opening up opportunities for predictive maintenance and lifetime insurance models.

Field Data from Home Storage Systems (RWTH/ACCURE, 2024)

A study of 21 residential energy storage systems across 8 years (14 billion data points) showed that predictive analytics could reliably estimate capacity fade at ~2–3% per year. The validated method matched manual field capacity tests and enabled better warranty planning, proving that predictive analytics can scale to real-world, fleet-level systems.

These cases demonstrate that predictive analytics isn’t theoretical, it’s already improving lifetime forecasting, warranty claims, and operational planning across industries.

Build the Trusted Foundation Together

The constraint isn’t only chemistry or cost, it’s confidence. SMART’s predictive analytics turns vessel and pack data into actionable foresight, enabling longer life, safer operation, and bankable economics.

By David Ventura, Co-founder Smart Battery Analytics

Source notes (key references used above)

Battery market & adoption context; AI across the value chain

SOC/SoH estimation pitfalls and analytics benefits (LFP focus)

Fleet-level field validation of predictive analytics

Real-world deployments:

○ Norled Ampere (Norway) background and operations.

○ Ellen E-Ferry (Denmark/EU).

○ Crowley eWolf electric tug (San Diego, U.S.).

○ Dutch/European electric barges and e-barge initiatives.