Electric motors have been used to propel boats since the late 1800’s, and since that time motor technology has operated under mostly the same configuration, deemed ‘radial flux’.

Recently however, a newer configuration has emerged that alters the location of one of the central components potentially giving the motor some serious benefits. This newer configuration is called ‘Axial Flux’. So which is better to use for an electric boat?

What is an electric motor?

An electric motor is a device that turns electrical energy into a rotational mechanical force. In the marine environment this force is used to turn propeller shafts, sometimes through a reduction gear, or turn an impeller in a water jet system with both systems enabling a vessel to move forward through the water.

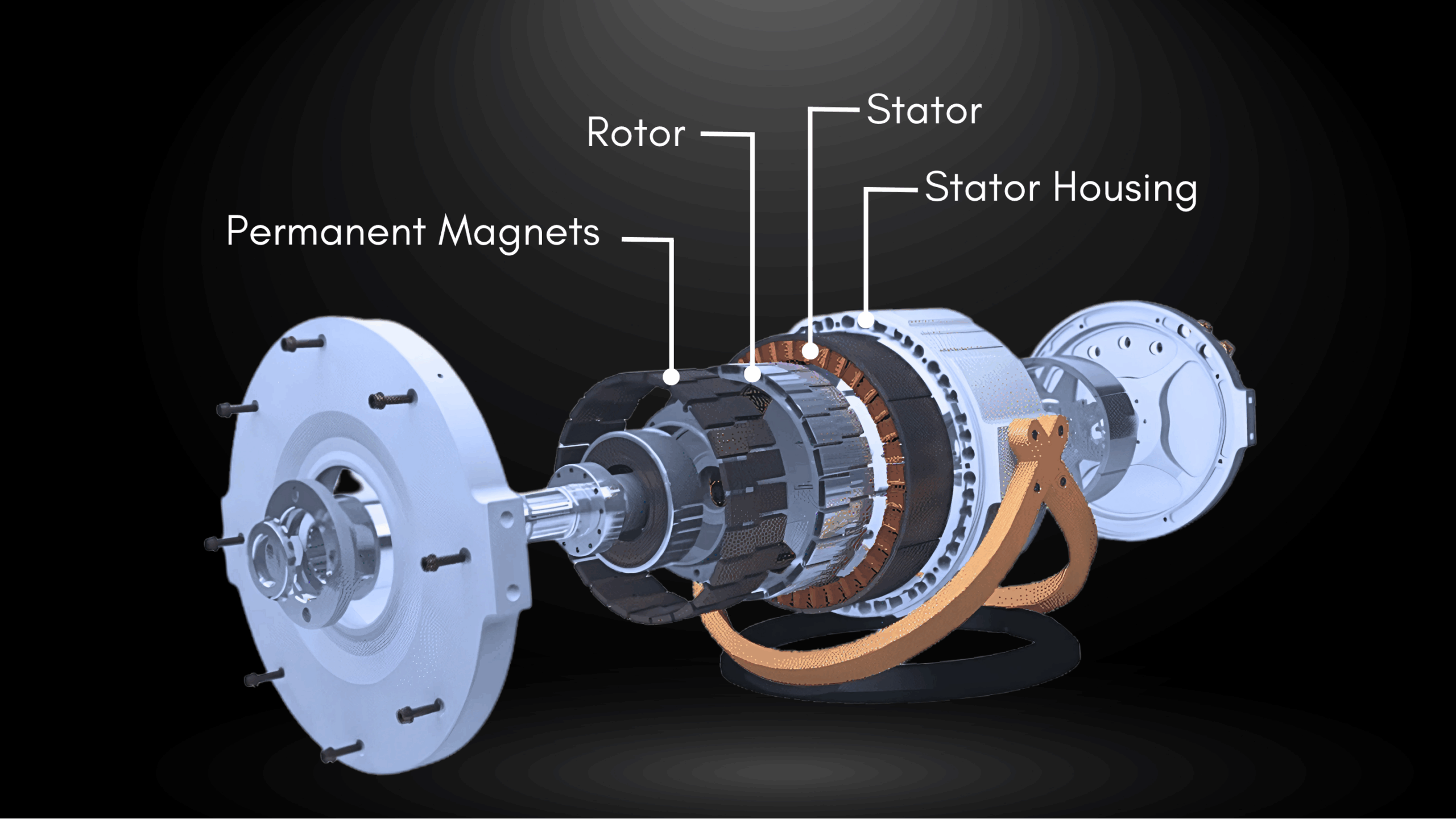

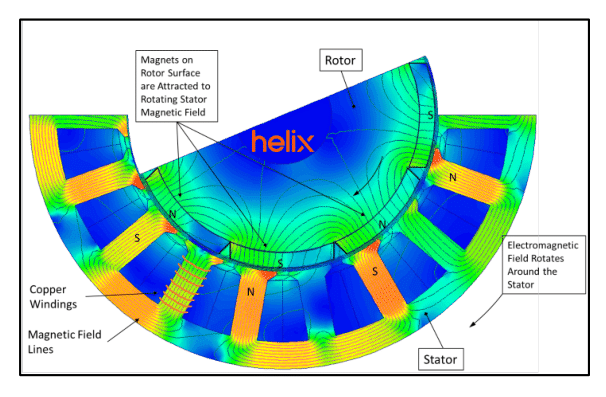

Electric motors universally contain a stator which remains stationary within the motor and provides a rotating magnetic field, and a rotor which rotates in response to the rotating magnetic field and turns a shaft.

The repelling magnetic forces are provided by permanent magnets, which can be located on either the stator, or rotor, and electrical wiring which are wound in coils and can also be located on either the stator or rotor.

Radial Flux Motor, source Boeli Group

Older motor technology saw the electrical windings on the rotor which were charged with ‘brushes’, or electrical contacts lightly brushing the coils to deliver current and spin the rotor.

Modern electric vehicle motors are ‘brushless’, and contain the windings on the stator, with the rotor containing the magnets and free spinning in the center.

Magnetic forces in a radial flux motor, source Helix

Axial and Radial, What’s the Difference?

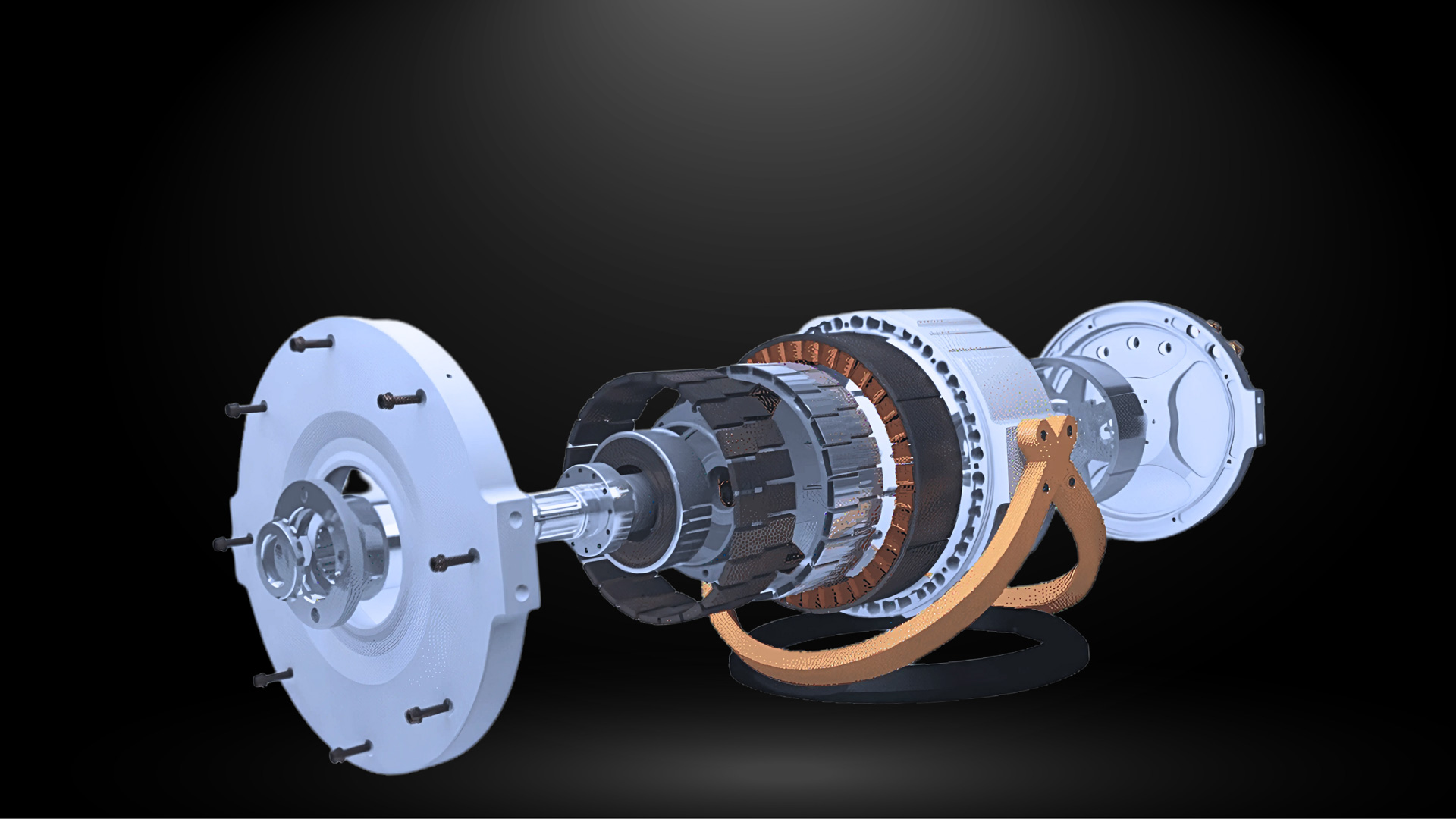

A traditional radial flux motor contains a cylindrical stator, and a rotor as a smaller cylinder, which rotates inside the larger cylinder.

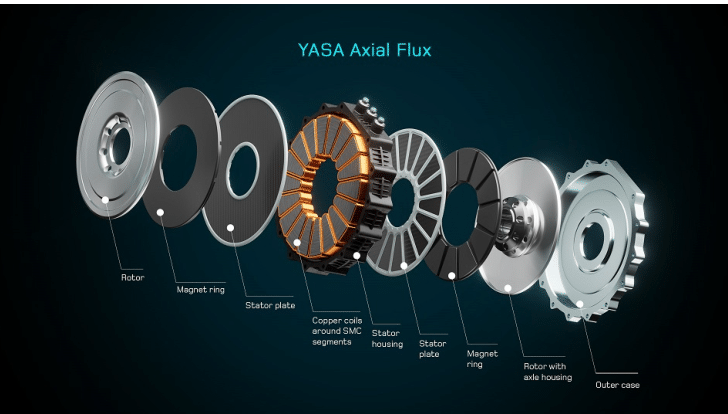

Axial technology changes this by instead placing the stator in the shape of a disc, and locating two disc shape rotors on either side of the stator. This has several advantages. First, force is applied along most of the diameter of the motor which radically increases torque density, unlike radial flux where force is applied only around the motor’s circumference. Second, because almost every part of the diameter of the motor is used to generate force, little space is wasted inside the motor. In a radial flux orientation, the center of the cylinder which contains no magnets or windings does not produce force or contribute to the turning of the motor.

Axial Flux Motor, source YASA

Axial Flux and High Torque Density

Torque is a rotational force, and the further away from the axis that force is applied, the higher the torque. Almost the entire interior volume of an Axial flux motor contains force producing magnets and coils, and force is applied along most of the diameter of the motor. Because of this, it can produce incredible torque density in a relatively small package.

Why aren’t all Motors Axial Flux?

On the surface given these advantages it would seem to make sense that all EV electric motors would gravitate to an Axial orientation. So why aren’t they?

As great as the torque and power density is with Axial flux, it also comes with some limitations.

Power in an electric motor can be increased in 3 ways. Increasing its diameter, increasing the speed, and increasing the length. Because in the Axial flux orientation magnets are sintered to the surface of a spinning disc, the further away from the center axis they are and the faster it spins, the greater the centrifugal force on the outer magnets. If the motor spins too fast, the magnets can separate from the disk potentially destroying the motor. This means that Axial flux motors are limited by speed, and to increase power they must increase the diameter of the motor which may not fit volumetrically in every application.

Additionally, since the orientation of the motor has the stator in the center, it is constrained by the outer rotors and cannot increase its length to increase power. This is why we see the phenomenon of motor ‘stacking’, attaching one Axial flux motor to another to spin the same shaft.

This is an effective method of increasing power, however integrators need to consider the addition of another inverter, cooling hoses, and pumps to meet the power and cooling demands of the extra motor in the ‘stack’.

It should be mentioned that radial flux motors can also appear in a ‘stack’ orientation as well. This most often occurs as a cost effective alternative to designing a bespoke motor with a longer orientation. Stacking radial motors removes the need for complex winding of longer coils, and having to source an inverter and battery capable of higher current flow and discharge, but comes with the disadvantage of needing a second inverter, another set of DC cables, and extra cooling hoses and pumps as well.

Lastly, there are manufacturing challenges with Axial flux not present with their radial counterparts. In addition to an immature manufacturing infrastructure, there are specific challenges when producing the stator as it is in a 3D geometry when compared with the 2D orientation in radial flux which can be easily produced by stacking laminations. This difficulty in manufacturing often translates to an increased cost when compared with radial flux.

The Marine Case for Radial Flux

Given the constraints of hull shapes and small machinery spaces on boats, the ability of radial flux motors to produce power by increasing length, diameter, or speed lends itself well to finding a solution to fit any particular space. If a motor needs to be located close to the propeller shaft, there is a limit to the diameter in the motor given the location of the hull, and a longer narrower radial flux motor might be used.

Manufacturing facilities for radial flux are also very mature enabling production at scale and often lower costs. This also means it is relatively easy to find a producer of radial flux motors local to any region.

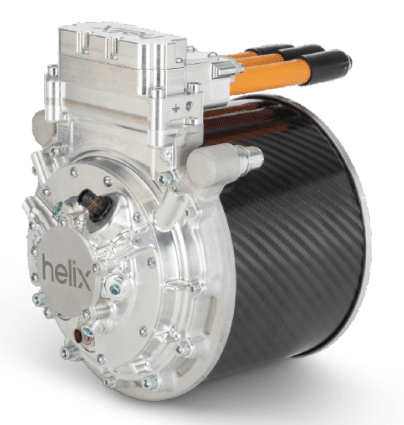

High Performance radial flux motor, source Helix

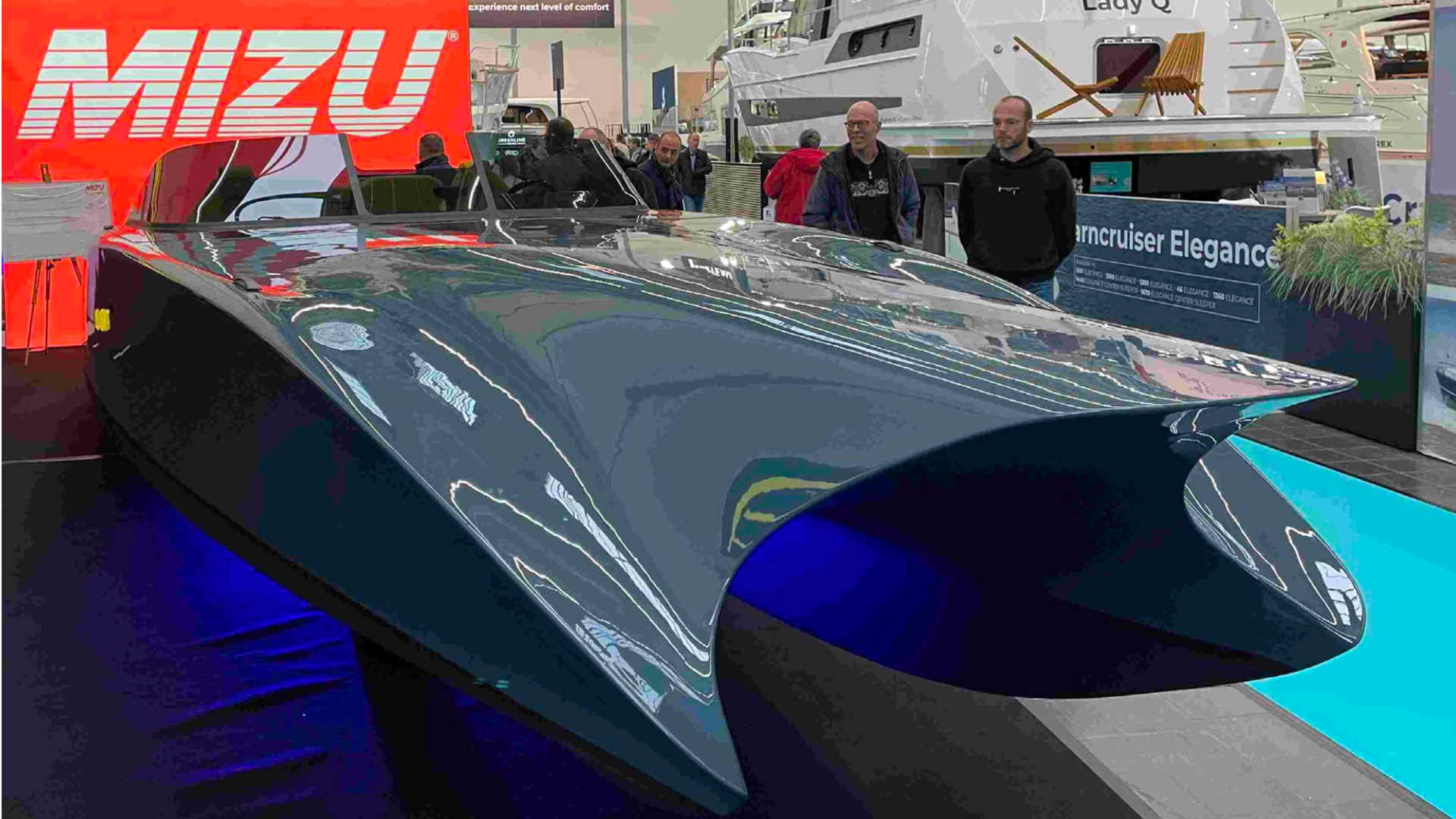

Radial flux motors have already been used successfully in many fully electric vessels. Manufacturer Boeli Group makes AC synchronous permanent magnet radial flux motors, and has supplied motors for many fully electric boats from high performance Marian Electric boats, to retrofits of classic sport yachts including Rivas, Boesch’s, and Pedrazzini’s through electric propulsion company NT Systems.

Many of the leading high powered electric inboard and outboard companies such as Evoy, Photon Marine, Vision Marine, and the aptly named Flux Marine are also using radial flux orientation, most likely due to its lengthy proven operating characteristics.

For those seeking truly top tier performance, UK based company Helix has a background in Motorsport, and produces radial flux motors with staggering power to weight ratios due to their proprietary cooling technology as well as several other advancements in material usage and engineering.

The last point to mention has to do with the rise in popularity of ‘hub motors’, or electric motors that are directly inline with the propeller which is a design that is really only practical in a radial flux arrangement due to the torpedo shape the motor must assume. While possible with Axial flux, the flat and wide orientation of the motor would likely cause too much drag to function properly as a hub motor.

The Marine Case for Axial Flux

Axial Flux’s popularity in recent years has risen due to research conducted by YASA company founder and CTO Dr. Tim Woolmer back in 2005. He was looking for a way to increase efficiency of the electric motor, and came across a rudimentary axial layout created by Michael Faraday back in 1821.

YASA, which is now a subsidiary of Mercedes- Benz inc. has since solved many of the cooling and manufacturing issues that plagued many of the early motors, and has become a viable option for powering Marine vessels. In fact, YASA’s axial flux motors have been powering marine vessels for over a decade. In 2018, a double stacked YASA axial flux motor helped propel the Jaguar Vector race boat to a then electric speed record of 88.61mph (142.6 kmh).

Jaguar Vector electric race boat with YASA axial flux motor

Electric propulsion system company Evoa successfully utilizes a double stack YASA axial motor configuration to power several fully electric vessels, including a fully electric Willams EvoJet tender. They have also electrified Chris Crafts and Supra wake board boats proving the versatility of axial technology.

Other companies are adopting axial flux motor technology as well. Electric outboard company RAD Propulsion utilizes an axial motor to power its outboard system, crediting the axial orientation with its extremely low profile, sitting almost parallel with the top of the transom.

Axial flux motor producer Beyond Motors are also in the marine space, suppling an axial flux motor to the University of Michigan’s electric boat racing team.

Which Orientation is Best?

Both Axial and Radial flux motors can be performant options for electric vessels, and the answer really depends on the specific use case. Depending the orientation of available space, type of propulsion system, and cost, either motor system may work. The biggest advantage Radial flux probably has over Axial flux is the lengthy history of usage and available data, but with the rise of several Axial flux motor manufacturers and more and more motors being used in real life applications we are starting to see axial technology proven out as well.