This excerpt is posted with permission from a report originally published by the Winston Churchill Memorial Trust, and can be found in its entirety here.

Candela is a specialist electric boat builder based in Stockholm, Sweden that has grown to over 200 staff since starting in 2014 and has built up a global distribution network. It was seeing the sleek Candela C8 recreational electric boat on display at the Sydney International Boat Show that first started me thinking marine rescue organisations need to understand the implications of alternative propulsion.

As attractive as the C8 is, however, it is Candela’s commercial P12 model, a 12m carbon-fibre foiling catamaran, that may have the biggest impact on the global market. Two P12s have been built, and one, the ‘Nova’ is in full commercial operation carrying up to 30 commuters on Stockholm Harbour (see photo on p.20). I was fortunate enough to experience this boat, and it impresses immediately with its bow-opening door and extendable ramp that makes boarding easy. But it’s the unseen technology that makes the difference, like the hydrofoils that seem to effortlessly lift the vessel out of the water. These active foils do not rely on flaps like most active foiling systems, but are flexed by electronic actuators in response to constant input from the sensors and control system up to 100 times per second to ensure a smooth ride.

The boat can foil in sea conditions up to 1m significant wave height, and the foils retract to allow the boat to rest on the bottom at low tide levels. The foil system has also been collision-tested, and in the worst case when a foil is damaged, hull integrity is maintained and foils can be replaced.

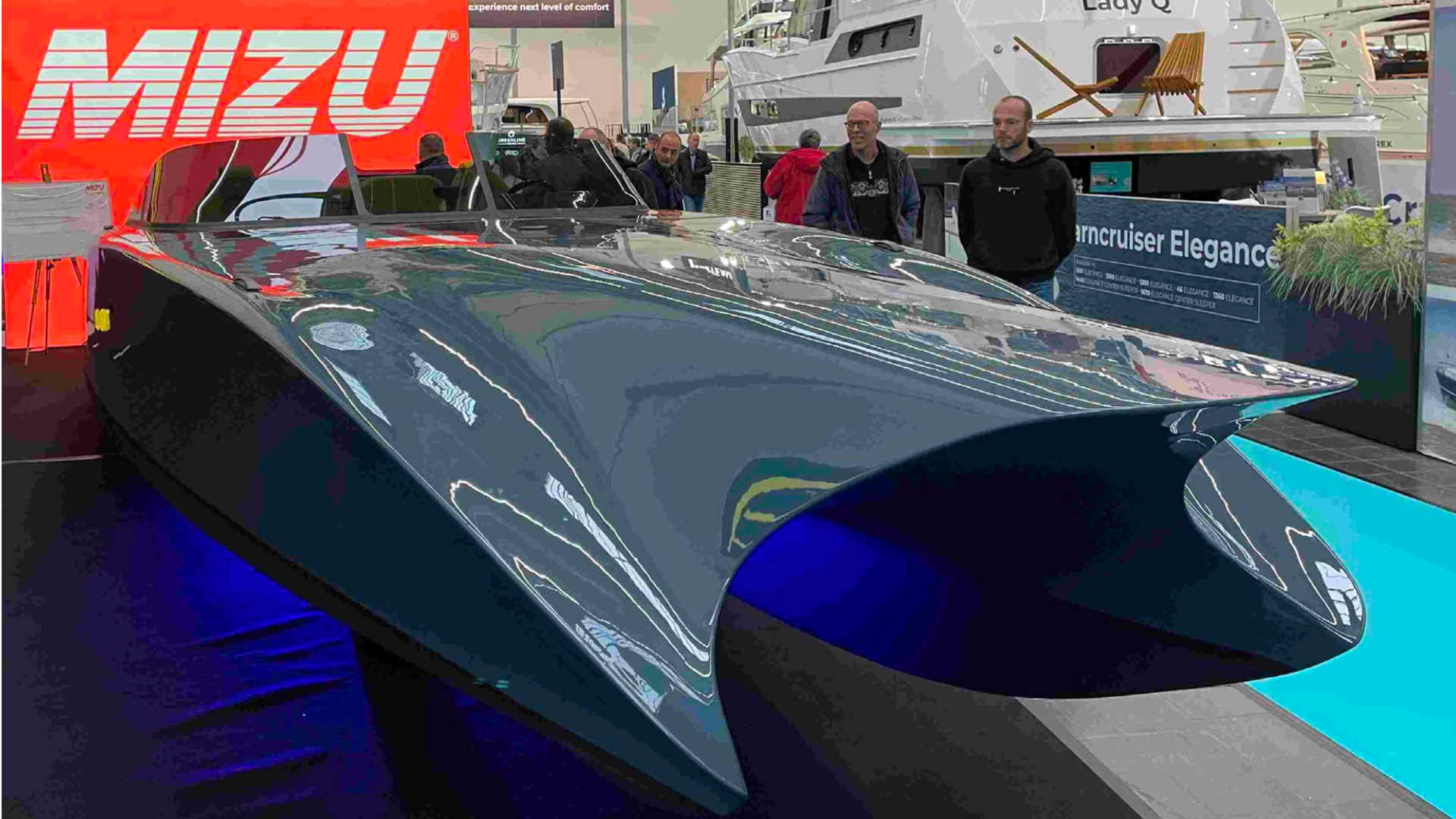

The Candela C8 wouldn’t look out of place in a Bond film.

Photo: Candela

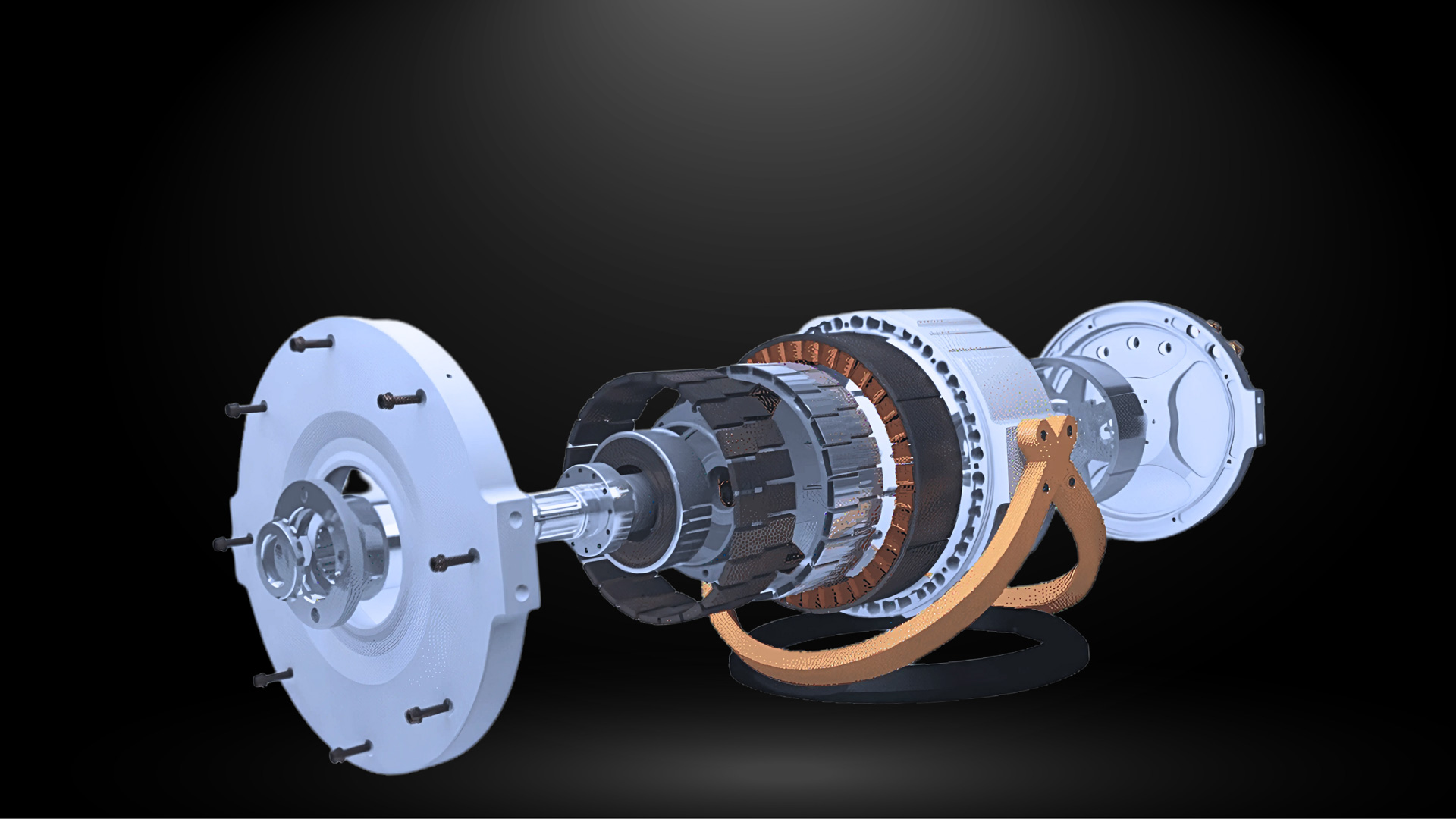

Propulsion as art: The Candela electric motor and foil module.

Photo: Candela

Also impressive is Candela’s unique and slim 400V 160kW peak power propulsion unit, with two electric motors in line and two counter-rotating propellers. It’s a beautiful piece of engineering in its own right, and it gives the P12 a top speed of 30 knots. Cruising at 25 knots, the 378kWh battery capacity gives a 40 nautical mile range. Propulsion systems are DNV certified, and Candela has made significant investments in safety, with multiple safety systems and redundancies including gas detection & venting systems, fire detection, warning and suppression systems, with both passive and active fire protection and of course an advanced BMS to prevent any of these being needed. Candela have sold around 200 boats and have not seen a battery overheat.

The efficiency of the P12 means it generates almost no wake, and it is allowed to operate at speed in Stockholm where traditional vessels are subject to strict speed limits. I can see this vessel working well in a few contexts such as river commuter routes and island/resort transfers in smooth or partially smooth waters. Candela also builds variants of the P12 including a commercial model configured as a Pilot Boat, and they received orders for 30 P12s in 2024 including for a river ambulance for the Amazon in Brazil, and anticipate doubling that in 2025. In addition to riding the P12 I was shown around the factory and met some of the production team, and it looks and feels like a tech company, which I suppose it is. I was impressed by everything I saw at Candela, and the C8 is the boat I wish I could afford!

Steber International/Ampcontrol Hybrid 12m commercial vessel

Steber International is a leading Australian boatbuilding firm that has provided many vessels to commercial operators including marine rescue organisations. In 2020 Steber launched a 6.7m hybrid vessel prototype, and Steber has now collaborated with Ampcontrol and the University of Newcastle on a 12m vessel. The 12m boat is a serial hybrid, with propulsion only from the two 300kW electric motors, and the 350kW on- board diesel generator providing additional power to the motors and/or charge to the six large LFP batteries.

The Steber hybrid 12m commercial vessel on the Hunter River in Newcastle

From the helm this vessel feels instantly familiar to anyone with experience operating conventional twin diesel Steber vessels, and when Alan Steber and Steve Mitchell of Ampcontrol took me for a demonstration on the Hunter River I was impressed by its silent and smooth operation at up to 7 knots. Above this speed the operator can choose to run on electric power only for a top speed of 18 knots (though with limited range), or to have the diesel generator provide additional performance up to 27 knots, cruising at 18 knots with the potential for an equivalent range to a conventional twin diesel boat depending on fuel carried.

For rescue organisations that need the range to perform SAR operations 30 or more miles from the coast, and that may be tasked with another rescue operation as soon as they come back to port, vessel range is a key consideration and a significant barrier to adopting pure electric propulsion, but a hybrid system like this may be a viable alternative, with potentially no range or performance penalty. The ability to run silently when conducting a search (usually done at low speed), allowing the crew to hear a sound signal or call for help, could also be a significant advantage for SAR operations. I can also envisage this kind of technology being ideal for service vessels and enforcement or port security vessels.

Ampcontrol has a great deal of experience in the mining sector, and significant expertise has gone into the BMS that manages the 600V system, with each battery cell in its six batteries individually monitored, including when the vessel is berthed. Safety measures include 3mm stainless steel battery compartments for each battery vented to the outside, isolation mechanisms, a glycol battery cooling system with a seawater heat exchanger, and everything is IP67-rated, so the engine compartment can flood without risk of a short circuit. The vessel complies with multiple standards and is being brought into DNV certification.

Significantly in terms of the potential for future decarbonisation of the Australian vessel fleet, the system can be retro-fitted to just about any shaft- drive hull, including the many Steber twin diesel vessels currently in service (my organisation alone has 9 of them, see photo on p.8 for an example). The system can be matched to operational needs, with the batteries, generator and fuel tank made larger or smaller depending on the application. A built-in dedicated charging system means the boat can charge anywhere 3-phase power is available. That a hybrid vessel could already offer a similar capability and experience to a comparable ICE vessel, albeit at some additional initial cost, but with significantly lower fuel costs, suggests we will see more of this technology on our waterways.

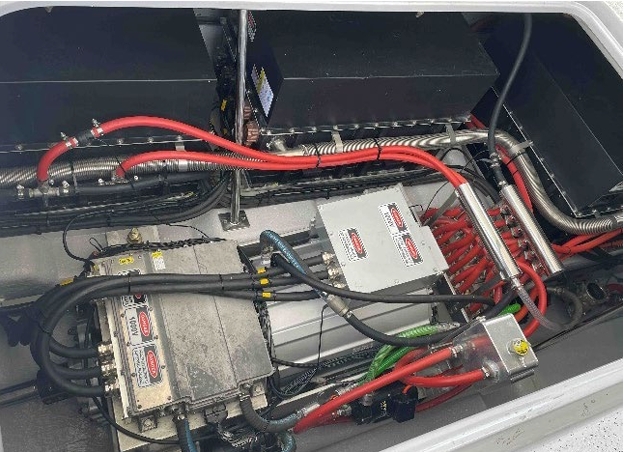

One of the electric motors powering the Steber hybrid vessel, with its control unit and three of the six black battery cases on board

RAD Propulsion RAD40 electric outboard

The impressive RAD40 outboard in the Southampton factory

RAD Propulsion is a company based in Southampton (UK) founded around five years ago with an electric outboard called the RAD 40, a 400V, 40kW, 98kg motor (equivalent to around 55hp) that has been in full production for about a year with around 100 units delivered and in service in Europe, the UK and USA. The motor is very well-engineered, with a pancake motor in the upper unit driving a simple gearbox (electric propulsion means the polarity can be reversed for reverse thrust, so there is no need for a gearbox to shift between forward, neutral and reverse, making for a simple, highly efficient and reliable gearbox). The outboard has an internal glycol cooling system with a heat exchanger in the cavitation plate, so cooling comes from the sea or lake but with no salt water circulating through the motor internally.

The RAD40 fitted to a 6m vessel, note the low profile of the motor and the space freed up by not requiring an outboard well

While recognisably outboard-shaped, the RAD 40 has a very low profile on the transom of a vessel, and as only the lower leg turns to steer, the upper part of the motor can be surrounded by deck with no need of a large outboard well, meaning more space is available for seating and storage while still allowing the motor to tilt up. The lower leg turns a full 180 degrees, meaning the vessel is highly manoeuvrable and can turn within its own length.

RAD Propulsion offers 21 or 61kW/h batteries, which can be installed in combination for more capacity. The batteries and all system components are integrated and controlled by a highly sophisticated BMS for efficiency and safety, and both the motors and batteries are IP67 rated in case of immersion. A separate 12V system is installed to run the battery monitoring and house systems, so the 400V system is inactive when propulsion is not engaged. The BMS can be adapted to other batteries and even voltages, since batteries are not easy to ship around the world and the motor may be coupled with other batteries in some markets. A sophisticated and customisable display is offered that will, among other things, analyse the most energy efficient speed for the current course and conditions, and the system can also integrate with established MFD systems.

The RAD 40, fitted to a RS Pulse 63 centre console hull, is in service with the Dutch National Police, with a top speed of 23 knots, a range of 25 nautical miles at 20 knots and a range of 100nm at 5 knots. I drove the centre console pictured above on the River Hamble, and in around an hour of travelling at 6 knots the battery charge level only dropped by 5%, and it was quiet, smooth and serene. I enjoyed every minute operating this vessel, and I could easily imagine many boaters having a similar positive reaction when they experience quality electric propulsion for themselves.

The RAD 40 can also be used on large houseboats, with different propeller options, or with foil-assisted vessels, or even in a hybrid system with ICE outboards. RAD Propulsion are developing other models both smaller and larger, and has an agent in Australia. The RAD40 is clearly a premium, high quality electric outboard, and I can see this company having a big impact as its line- up grows.

The helm display provided with the RAD40 outboard, showing the battery capacity at 95% even after I drove it for a full hour at 6 knots

Artemis Technologies EF12

Artemis Technologies was founded in 2017 in Belfast to translate the foiling expertise and success of the Artemis Racing Americas Cup team into more sustainable marine technology for the broader industry. Their first electric foiling vessel, the Pioneer of Belfast, was launched in 2022, and their 12m carbon fibre foiling hull now has several variants for different commercial applications including water taxis, pilot boats, patrol boats and workboats.

While they haven’t ruled out a recreational boat in the future, for the moment Artemis is focused on the commercial vessel market, and is widely considered one of the leaders in the field.

I was able to see and experience the rather luxurious Artemis EF12 Escape model in Miami, where it was brought to coincide with the Miami International Boat Show. Heading out on a moderately choppy Miami Harbour and cruising at around 22- 25 knots, the active foils made for a very smooth ride that felt very much like flying and was nearly silent. The EF12 has a top speed of 32 knots and a 47 nautical mile range when foiling, producing almost no wake at all in the process. The EF12 certainly attracted a lot of attention around Miami, with shore-based and boat-based onlookers alike stopping to watch the futuristic boat glide by, and I couldn’t help but think any marine business that adopts this kind of boat will have a ready-made attention-grabbing machine.

The EF12 Escape is one of several variants that include commuter boats and work boats, all using the same hull and fixed foils for simplicity and robustness. The single 270kW motor in the forward foil and the impressive 800V, 412kWh battery have both been developed by Artemis Technologies, along with the proprietary charging system that can fully charge the battery in one hour. Artemis Technologies has worked with both DNV and Lloyds to ensure every possible safety redundancy has been incorporated, including a fire suppression system specifically designed for lithium batteries.

Five 12m Artemis vessels have been built, and some are already in commercial use, with orders for many more. Artemis Technologies also have several EF24 electric foiling 24m ferries in production to operate in Puget Sound, USA, and across the Solent from Southampton to the Isle of Wight in the UK, and I doubt it will be long until we see something like this in Australia.

I felt like a movie star riding around Miami on the Artemis Technologies EF12 Escape, enjoying its smooth ride on Miami Harbour, with every head turning to look!

The EF12 Escape and EF12 workboat models on their foils. Photo: Artemis Technologies

E-Propulsion electric outboard and inboard propulsion systems

In looking at the electric propulsion manufacturers having the greatest impact on the marine market, two brands mainly known for their electric outboards stood out as the big players with many more sales than others, so I reached out to both requesting an interview, and one replied. Thus it was that I found myself speaking with the CEO and founder of E-Propulsion, Danny Tao, and meeting with the Managing Director of E-Propulsion UK, Steve Bruce, and Head of Training & Compliance, Simon Boyde, and learning a lot about the engineering that goes into their impressive and multi-award-winning range of products.

E-Propulsion started in Shanghai in 2012, commenced production in 2016, and currently offers six models of 48V outboard, three models of 96V outboard models, four pod drives, four inboards, and four models of battery, ranging from the small blade-shaped ‘eLite’ 500W portable outboard up to 250kW inboard units for large vessels. With around 60,000 units in service in 60 countries around the world and annual production of over 12,000 units, E- Propulsion has made quite an impact on the market, and I saw their products in use in many locations I visited. E-propulsion also has distribution in Australia, and has sold many small outboards here, particularly the Spirit 1.0 model aimed at tenders that is not only light weight but floats if dropped in the water, as well as many Pod models, including one Pod 3.0 model installed in a historic timber putt-putt boat on the Colo River. Now that E-Propulsion also has larger I-series inboard units available, with hundreds fitted to vessels around the world, it seems likely we can expect to see these in Australia in the future, too.

E-Propulsion manufacture their own LFP batteries, and are closely watching developments in battery chemistry with a willingness to adopt new battery technology when it is proven. They also supply chargers, and have a philosophy that performance and safety are optimised when the entire system from the motor and controller to the BMS to the battery and charger are designed to operate together. I was able to visit the E- Propulsion UK headquarters and see several products installed on test beds for training. These installations impressed me with the evident quality of components, and the installer training manual I was given access to goes into significant detail on ensuring the correct cables, terminals, fuses, switches, casings, mountings and waterproof barriers are used, and shows the importance of quality not just in the engineered product at the factory but also during the installation process.

Like many other manufacturers the BMS is regarded as the key to safe and efficient operation and, also like many other manufacturers, the BMS used by E-Propulsion has the ability to provide real-time data to the vessel operator, even remotely when the vessel is in storage.

E-Propulsion 96v outboards on display at Boot Düsseldorf, including the 40kW, 104kg, X40 model

E-Propulsion works with many boat builders to develop propulsion systems tailored to different models of boats, and while they admit this is much easier for boats designed for electric propulsion in terms of battery placement and its effect on stability and performance in particular, many retrofits have been completed on former ICE boats. Also, while their products are not tailored to foiling or hybrid systems, E-Propulsion are happy to support projects looking to use their products on foiling and hybrid boats.

One area of the European market where E- Propulsion has had an impact is canal boats,

which are perfectly suited to electric propulsion, being associated with a leisurely lifestyle where quiet, vibration-free power is immediately valued, and typically having ample rooftop space for solar panels. There are over 200 canal boats using electric propulsion in the UK alone, which is why when I visited E- Propulsion in Southampton they were training technicians from River Canal Rescue, an organisation that provides repairs, towing and general assistance to some of the 40,000 canal boat owners in the UK, a clear indication that those in the canal boat community expect the use of electric propulsion to continue to grow.

I was impressed not only with the products on offer from E-Propulsion, but also with their openness and their enthusiasm to promote new boating technology, both their own and that of others. They did not run down the products of their competitors, but seemed genuinely interested in developing high-quality, safe, reliable products they could take pride in, and supporting sustainable boating in any way they could. My interactions with the E- Propulsion team and their products made me feel optimistic about the future of boating, and I have no doubt they will play a major role in our market in the future.

The futuristic 7.9m Mizu Twiel Z7 on display at Boot Düsseldorf, fitted with two E-Propulsion I20 inboard motors

An E-Propulsion I10 inboard model on the test bed in Southampton

Yanmar hydrogen fuel cell technology

Yanmar is a large and well-established player in the marine propulsion market whose name has been synonymous with reliable diesel engines for nearly a century. Yanmar diesels power many recreational and commercial vessels in Australia including some I have owned and many I have operated, so I was excited to take up the invitation to visit the Yanmar factory in Osaka. Yanmar is impressively active in the development of alternative propulsion technology, on several fronts, and recognise the need for a range of low and no emissions options for powering the vessels of the future, with no single option able to suit all applications.

One simple option that Yanmar supports is the use of HVO in their diesel engines, and HVO is already in use in their products in many locations, limited only by its current uneven availability. Yanmar is also exploring the potential of methanol, ammonia and hydrogen combustion engines for large ships. And Yanmar has already developed an all-electric propulsion pod drive for yachts up to around 12m, which will be in production this year.

It was Yanmar’s hydrogen propulsion technology that drew me to Osaka, however, as they are a clear leader in developing hydrogen fuel cell technology for marine propulsion. Yanmar started their development of hydrogen propulsion a decade ago and have built two hydrogen fuel cell boats so far, with another currently under construction. Yanmar believe hydrogen fuel cell propulsion will be a viable solution for small and medium sized commercial vessels such as tour boats, fishing boats and tugboats, and they have demonstrated this with a 12m prototype test boat launched in 2021. This vessel, developed in partnership with Toyota Motor Corporation and others, is capable of over 20 knots and it looks the part – it is striking in its attention-grabbing red colour scheme and prominent H2 livery, but also looks conventional enough to show mariners that hydrogen fuel cell boats need not look like space ships, but will be very similar to the vessels we are used to working on – just quieter and with no emissions.

Yanmar’s 12m hydrogen fuel cell prototype vessel on Osaka Harbour.

Photo: Yanmar

The impressive Yanmar GH320FC hydrogen fuel cell unit

Photo: Yanmar

Yanmar have since taken hydrogen propulsion much further, developing self- contained fuel cell systems such as the GH320FC that have achieved DNV certification. Inside this large red and black unit are four 80kW fuel cell modules, hydrogen gas valve units, a heat exchanger cooling system and multiple safety systems including a built-in fire suppression system in a reliable, ready-to-install solution that can be used in single or multiple unit configurations. A three-cell GH240FC version is also available, and two of these are already powering the 33m ferry Hanaria that has been in commercial operation carrying passengers in Fukuoka, Japan for over a year. These units are not light, the GH320FC weighs around 3 tons and the GH240FC around 2.4 tons, so for the moment they will only suit medium and large sized vessels, and neither are they cheap at the moment. Nevertheless, Yanmar’s self-contained fuel cell system design might just be pointing the way ahead for commercially viable, smooth, silent, emission-free hydrogen-electric propulsion.

Boot Düsseldorf and Miami International Boat Show

My research trip was deliberately timed to allow me to visit these two boat shows, with Boot Düsseldorf being the largest in Europe and Miami being one of the largest in the USA, and neither show disappointed. Boot Düsseldorf had a very strong cohort of exhibitors showing electric boats, including Candela, Edorado, Marian, Lumen, Greenline, Twiel, X Shore, Ruban Bleu, De Antonio, plus many electric personal water craft and foiling boards. There were many electric outboards and propulsion manufacturers, too, both in dedicated displays and where hull manufacturers displayed boats with electric outboards fitted, including models from E-Propulsion, Torqeedo, Explomar, Evoy, Aquamot, Remigo, E’dyn, Falcon, Welle, The Kinetic Option, Parsun, Mercury, Yamaha, and Honda. Boot Düsseldorf also hosted a Blue Innovation Dock, with talks on new marine technology, much of it focused on sustainable propulsion and materials, as well as marine AI applications and more.

Just one of the seventeen huge halls of boats displayed at Boot Düsseldorf

I expected electric boating to be well- represented, but even so I was surprised at the number and range of electric options on display, and also at how unremarkable this seemed in the context of the show overall – it was clear to me at Boot Düsseldorf that, in Europe at least, electric boating has arrived as an accepted mainstream consumer option.

In Miami there were fewer alternative propulsion products to see and less of an emphasis on sustainable boating. Many of the electric vessels were displayed in a separate small ‘Progressive Pavilion’ outside the exhibition centre, giving the impression they were somewhat outside the mainstream, and where, at least on the hot day I visited, they weren’t seeing much traffic. This was a pity, as there were some very nice boats on display, including some powered by Flux Marine, a Rhode Island manufacturer that builds a refined- looking 100hp belt- driven electric outboard. In the main hall a few electric outboard manufacturers had displays including Mercury with its growing electric range, and Yamaha displayed its hydrogen combustion outboard and the boat that is being used to test it in the USA.

At the marina displays there were some vessels running Suzuki and Volvo- Penta engines on biofuels giving demonstrations, supported by the National Marine Manufacturer’s Association and ICOMIA, and E-Motion displayed its electric and hybrid propulsion systems suitable for new or retrofitted large cruisers and superyachts. Wandering around the show, however, and watching the boating traffic around the city, it was clear that the fashionable choice for Miami boaters is as many of the largest outboards you can afford – around the harbour and at Haulover inlet I saw many sleek high-performance sports cruisers with four, five or even six huge outboards!

Electrified Marina, Norfolk Virginia

In Norfolk, Virginia, best known for having the largest naval base in the world, Electrified Marina is focused on bringing electric boating to recreational users, offering electric boats and propulsion systems, installations including retrofits, and electric hire boats. Given I was in the neighbourhood to meet the US Coast Guard, I reached out to owner Erick Pinzon for a visit. Erick met me one cold grey morning and showed me some of the electric vessels for sale from several manufacturers including a X Shore 1, a Scout speed boat fitted with an electric outboard made by Flux Marine, and a very comfortable-looking Ingenity 23E pontoon boat from Florida which has an electric motor coupled to a Mercruiser stern drive leg that gives it a top speed of 25 knots. Erick and his team also install electric propulsion systems from a few different companies, including E- Propulsion, and have done six electric propulsion retrofits so far and a hybrid retrofit underway, which he acknowledges can be a challenge, particularly if the vessel is tight for space.

I saw lots of boats like this at the Miami show, and around Miami generally. I’d love a drive, but not the fuel bill!

The X Shore 1 and behind it the Ingenity pontoon boat at Electrified Marina, Norfolk, Virginia.

Aqua Lectric shot a video at Electrified Marina just days before my own visit, which can be viewed on the Aqua Lectric YouTube channel.

Most of Erick’s customers are at least partly motivated by environmental concerns, however once they experience electric boating, he says, they enjoy the experience, particularly the quiet operation. Erick also told me that new boaters find electric boats easy to use and unintimidating, with not too much to learn before getting onto the water and very little maintenance. This is also true of his electric hire boats, which are fitted with E-Propulsion inboard systems and have been operating with no trouble for five years on the original batteries, and Erick noted he would have replaced ICE outboards twice in that time.

Erick believes electric propulsion systems are at least as safe as conventional ICE systems if installed and operated correctly, and has good knowledge of the many safeguards built into the systems he sells and installs.

I asked Erick how he sees the future of electric boating in the USA, and he clearly has a good understanding of the challenge before him. Erick believes much of the marine industry relies on maintenance and repairs for their business model, and since electric boats are simple and reliable and don’t contribute much to these income streams, it will take a significant adjustment in the industry to fully support them. He expects improvements in battery technology and affordability to help drive uptake, and since the USA sees around a quarter of a million new boat sales each year, even convincing 1-2% of these customers to choose electric propulsion will have a significant impact on both the market and the environment.

The two Electrified Marina hire boats have had a trouble-free five-years with E-Propulsion systems